Vamco Introduction

Vamco, a vehicle axle manufacturing company, was established on January 20, 1988, to produce and assemble front and rear axles for diesel vehicles. The establishment was financed by the Bank of Industry and Mine. For this project, representatives of the bank held negotiations with companies such as Benz (Germany), Mann (Germany), Raba (Hungary), Volvo (Sweden), Iveco (Italy), Eaton (England), GKN (England), Steyr (Austria), and Krupp (Germany). Only Volvo, Iveco, and Benz responded positively to the negotiations. In late June 1988, following numerous negotiations between the Organization for Industrial and Mining Development and relevant companies, it was agreed that the Development Organization would also be involved in this project through related companies. Eventually, the share composition of the Vehicle Axle Manufacturing Company consisted of 89.3% Iran Khodro, 3.2% Iran Khodro Diesel, and 7.5% others. In 1990, after the negotiations, the Development Organization proposed a change in share distribution, suggesting 75% for the organization and 25% for the bank. However, due to the bank’s opposition and disagreements arising from a lack of understanding, the project was halted in the same year.

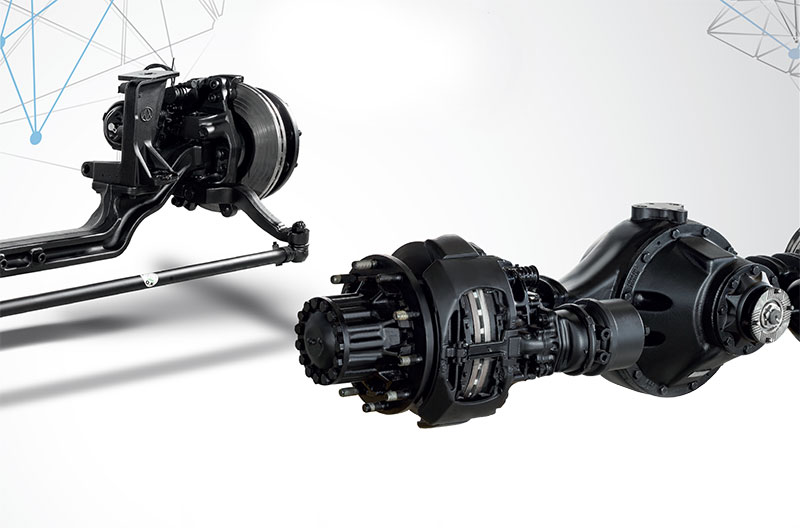

Production Operations

Heat Treatment Operations: This facility, equipped with gas carburizing furnaces, is capable of performing heat treatment and hardening operations on approximately 3 to 6 tons of various manufactured parts both from within and outside the company. It also can perform hardening operations on various axle shafts, housings, gearings, as well and as conduct crack testing using an MPI (Magnetic Particle Inspection) device.

Design and Engineering

Design and Engineering Affairs The Vehicle Axle Manufacturing Company, utilizing the capabilities and creativity of specialized experts and employing state-of-the-art technologies, is engaged in the design and production of heavy, semi-heavy, and light vehicle axles. It also aims to innovate, create product diversity, improve quality, and increase production capacity through continuous efforts and the utilization of modern engineering software such as CATIA, ABAQUS, ADAMS, and ANSYS. Continuous training of employees, enhancing their scientific and technical capabilities

Vehicle Axle Quality

Control of incoming parts in the Vehicle Axle Manufacturing Company is performed using experienced professionals and advanced inspection tools, including CMM (Coordinate Measuring Machine), metallography, quantum meter, salt spray, tensile and compression testing, and various hardness testers. Evaluation and control of manufacturing processes of suppliers. Holds ISO/TS 16949:2009 – ISO 9001:2008 – ISO 14001:2004 – OHSAS 18001:2007 IMS certifications.